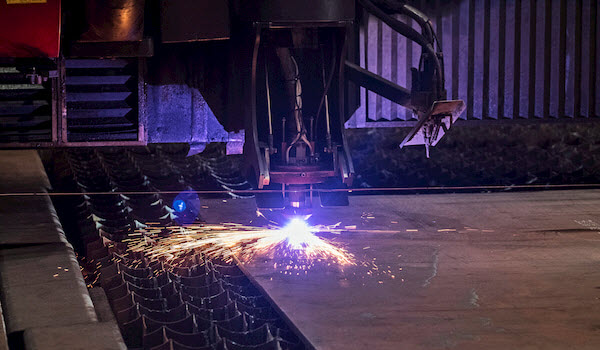

The combination of cut quality, productivity, operating cost and versatility make plasma today’s most popular industrial cutting process.

Plasma cutting technology

A plasma cutting system uses the plasma arc, a directed stream of ionised gas, to transfer energy and cut conductive metals, including mild steel, carbon steel, stainless steel, aluminium and other metals.

It works at ultra-high temperatures of over 2000 degrees Celsius. The plasma arc cuts the workpiece by melting it and blowing away the molten metal.

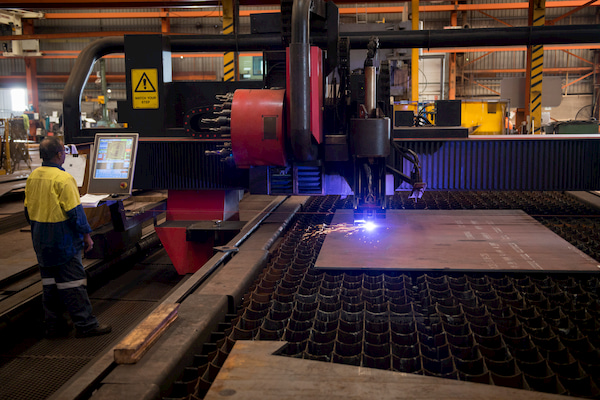

High productivity and precision

Rigby Jones uses HyPerformance plasma cutting systems that are designed and built for maximum performance and productivity.

Our plasma cutting capability allows us to process extra-long lengths up to 21m, making it ideal for applications across a wide range of industries, including agriculture, transportation and mining.

The system combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability, and delivers the ultimate in mild steel cutting, plus aluminium capability and unmatched stainless steel cut quality.

- Straight cutting

- Hole cutting

- Fine feature cutting

- Marking

- Underwater cutting (to reduce the warping and distortion of cut components)

| Plasma | Carbon Steel Max Thickness | Stainless Steel Max Thickness | Max Width | Max Length |

| 36mm | 32mm | 3.2m | 21m |

In-house expertise

At Rigby Jones, we specialise in the complex cutting and forming of mild steel, quench and tempered steel, corten steel, stainless steel and aluminium of all grades. All of our steel is supplied to Australian standards, and our work is ISO 9001 certified.

Our expert team works with clients to deliver solutions tailored to your specific requirements. We provide recommendations on how a component can be pressed, cut or shaped to deliver best quality and a cost-effective outcome.

Our state of the art design software integrates with our metal cutting and forming capability and specialised nesting software to minimise waste and maximise value. Our team is committed to quality at every stage of your project.

Are you looking for a custom steel solution?

At Rigby Jones, your supply and steel processing requirements are met under one roof. Find out more about our expertise.

Call Us

Call Us